Safety Banners for safety awareness Awareness - Premium, Nylon Reinforced Vinyl.

100% Industrial Outdoor Grade - Always Digitally Printed.

Our Safety Awareness Banners are used by 87% of the Fortune 500!

CLICK HERE for all our safety banners.

NO cheap 10 ounce plastic material.

NO cheap 90's looking vinyl cut lettering / graphics.

ONLY Premium Outdoor Grade Nylon Reinforced Vinyl - the very BEST!

WHY - Our reputation was built on High Quality & GREAT customer service!

100% Premium Quality Industrial grade Safety Banners manufactured on state-of-the-art digital vinyl banner printers. (Yes, they are huge.)

CLICK HERE for our NEW safety store, Safety Banners USA (safetybannersUSA.com)

ALL of our Safety Awareness Banners are printed on Top Grade, Premium Nylon Reinforced vinyl capable of lasting OUTDOORS for 3 to 7 years. Indoors, they will probably last 50 years. All our safety awareness banners are fully hemmed with reinforced grommet holes at each corner. Our industrial grade safety banners are fully fade resistant weather proof so you can use them both outdoors and indoors with confidence. Nobody produces higher quality workplace safety banners for your safety awareness program than SafetyBanners.Org - nobody. (We do not manufacture an INDOOR ONLY banner as the lower cost non-vinyl materials are not suitable for hanging.)

Our Very First Safety Banner Design.

We add new safety awareness banners monthly, so check back often to see what new we have to offer. The Recently Added Category, will have all the safety awareness images and safety banners we have added in the past month. Industrial safety Banners for industry safety awareness programs are becoming recognized as the BEST way to increase safety awareness with both the employees and management. OSHA, and it's VPP program, recommend safety awareness promotion using banners. We are here to help. When you call, you will talk to real people and get real answers. Our founder always said, "We are really in the customer service business. We just happen to also sell work place safety banners." Thank you for your visit here and your time. We appreciate it.

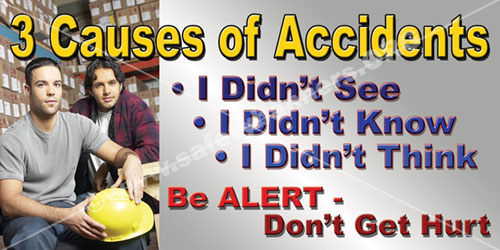

Safety banners are highly visible, but need to be designed by professionals with the impact on the viewer in mind. Most of the safety banners are low impact, uninteresting and visually lacking. This is because most companies do not have the capability and equipment to produce stunning graphics and imagery like we do. Furthermore, most of the designs come from the 80's and 90's and suppliers have failed to update their safety banner designs and make them more contemporary. SafetyBanners.org has trained professional designers on staff who design all our products! It is almost an insult to your employees to put up a banner with stick-like figures or clip art from the 80's and expect them to pay any attention to it. We have been told time and time again that our safety banners have much more impact than our competition and actually do help increase safety awareness. Cost is always a consideration. We can be a low cost leader in graphic safety product because our entire company is focused on digital graphics for safety and retail stores and are one of the largest companies in our industry.

Safety banners are highly visible, but need to be designed by professionals with the impact on the viewer in mind. Most of the safety banners are low impact, uninteresting and visually lacking. This is because most companies do not have the capability and equipment to produce stunning graphics and imagery like we do. Furthermore, most of the designs come from the 80's and 90's and suppliers have failed to update their safety banner designs and make them more contemporary. SafetyBanners.org has trained professional designers on staff who design all our products! It is almost an insult to your employees to put up a banner with stick-like figures or clip art from the 80's and expect them to pay any attention to it. We have been told time and time again that our safety banners have much more impact than our competition and actually do help increase safety awareness. Cost is always a consideration. We can be a low cost leader in graphic safety product because our entire company is focused on digital graphics for safety and retail stores and are one of the largest companies in our industry.

How Many Colors can my Custom Safety Banner Be?:

Unlimited! We have ZERO color limitations because we actually PRINT your safety banner. We have six banner printers very similar to the little color printer on your computer. The main difference is ours cost over $100,000 each and are 12 feet wide. Smaller shops use vinyl cut lettering which is low cost with the equipment costing less than $3,000 and can literally be done out of one's home, like the safetybannerstore.com and mrsafety.com.

Hanging a Safety Banner:

All our safety banners come with rust-proof grommets to make installation and hanging easy. See the graphic below to determine how many grommets your banner will have (they vary by size). For installation on an interior or shelter wall, merely pin the banner to the wall using the grommet holes. As an alternative, you may even drive a pin or nail through the hemline. When using twine or rope, attach the ropes on the top two corners and stretch the banner out to make it look great.

All our safety banners come with rust-proof grommets to make installation and hanging easy. See the graphic below to determine how many grommets your banner will have (they vary by size). For installation on an interior or shelter wall, merely pin the banner to the wall using the grommet holes. As an alternative, you may even drive a pin or nail through the hemline. When using twine or rope, attach the ropes on the top two corners and stretch the banner out to make it look great.

When hanging a safety banner from the ceiling, be sure to pull the corners tight so the banner does not sag in the middle. If it does, you might want to attach a third rope to the center grommet to hold the center up properly.

Dowel Rod Top Alternative for Ceiling Hanging Banners

For a small additional fee, we can hem in a stiff 5/8’s inch dowel rod into the top hem of the banner and place a grommet hole in each top corner. With this method, you can hang the banner from each corner and be assured your safety banner will not sag in the middle and hang straight. (up to TWELVE FEET MAXIMUM)

Hanging a Safety Banner Outside:

OUTSIDE Safety Banners MUST be hung taught!

The key to hanging any banner outside it hanging the banner TIGHT. Even calm areas of the U.S. occasionally get windy conditions. What destroys an outside banner (even the ultra heavy 16 and 19 oz. tent banner material) is the flapping vibration that happens during any windy time. This flapping vibration will soon rip out ANY grommet on ANY banner. Once one grommet is ripped, even just a bit, it is not long before other grommets are ripped and the whole banner is destroyed. This can happen in just hours.

OUTSIDE Safety Banners MUST be hung taught! Stretch the banner tight by all four corners and the center grommets if possible. A tightly hung banner will have a much better chance of surviving the wind when it strikes.

Windy Conditions and Fences:

Windy Conditions and Fences:

First, SafetyBanner.Org produces a product called “Mesh Fence Banners”. This material has small perforations in the material to allow wind to pass through and is designed specifically for windy conditions. We ALWAYS recommend this product. A standard vinyl banner may not last long in windy conditions.

All outdoor safety banners must be hung taught. Mesh Safety Banners MUST be hung taught using ALL the grommets on the banner if possible! Stretch the banner tight by all four corners and ALL the grommets if you can. For a MESH FENCE SAFETY BANNER on a fence, after stretching the four corners to make the banner tight, use strapping ties to attach all the other grommet holes to the fence. A properly hung banner will have a much better chance of surviving the wind when it strikes.

Wind Slits: Wind slits were invented in the 1960’s long before Mesh Fence Banner material was developed. For Wind slits to have the same wind release as mesh fence banner material, you need to place one wind slit every 3 square feet! This means that a 4’ x 8’ banner needs at least TEN WIND SLITS to be effective. We believe wind slits make a good-looking banner ugly and we rarely use them on a banner.

How Large Should my Safety Banner Be:

How Large Should my Safety Banner Be:

Size Does Matter. A 3-foot x 6-foot banner looks big from 15 feet, but inside a cavernous facility, it may look rather small. Our returning customers, who first purchase 3’ x 6’ banners, often purchase larger ones because the small sizes can look really small from a distance, like the center of a large facility. Remember, we can go as large at 10-foot by 20-foot with our standard designs. We can even produce a banner as large as 40-foot by 80-foot if you need one.

There is no real standard for safety banners, but we do have a suggestion that may help you decide. Have a pair of co-workers stand about 12 feet apart in your facility. Now step back to a distance from where you want your banner to be easily read and viewed. Essentially, you are looking at a 6-foot tall by 12-foot wide banner. (Unless you employ a large number of basketball players.) A 3-foot by 6-foot banner would be about half that size (waist high and half the width). What do you think?? 3-foot by 6-foot not a big as you thought? We know. Interesting isn’t it.

How Long Will my Safety Banner last?

The answer varies. Indoors, or in an outdoor sheltered area, about 50 to 100 years. Totally exposed to the elements all day long in the middle of Nevada, about 18 months to two years. In a Category 3 Hurricane, about 15 minutes. On average, outdoors, you can expect your banners to look good for 3 to 4 years.

ALL our safety banners are Premium Grade, Nylon Reinforced Vinyl designed to be used Outdoor and Inside. The keys to longevity are:

A.) How they are hung (see hanging a safety banner outside above)

B.) Where they are used (inside, outside, high wind, intense desert heat, etc.)

C.) Where you live – Minnesota, Nevada, Louisiana, Utah and so on.

Horizontal and Vertical Safety Banners:

Horizontal – Vertical – we do BOTH. SafetyBaners.Org is the ONLY safety banner manufacturer that offers ANY BANNER in BOTH Horizontal AND Vertical Format.

SAFETY from America's Largest Supplier of Safety Banners

CLICK HERE for all our safety banners.

CLICK HERE for our NEW safety store, Safety Banners USA (safetybannersUSA.com)

Safety banners can improve company moral as well as help reduce cost. Safety awareness can be enhanced with safety ba nners.

nners.

Safety is a relative term. Safety in the workplace can be both a morale booster and save company money. Several studies have shown that when a company makes safety a priority, employee productivity goes up, morale goes up and total cost goes down. Management discussing Safety and Health Topics with employees enforces a companies’ commitment to keeping it’s workers safe and healthy on the job.

Several studies have shown that when a company makes safety a priority, employee productivity goes up, morale goes up and total cost goes down. Management discussing Safety and Health Topics with employees enforces a companies’ commitment to keeping it’s workers safe and healthy on the job.

Complete assessments to determine performance gaps and improvement opportunities in your Safety Management System. This will help you to evolve a framework of safety processes and procedures that help your company to achieve its safety objectives, and integrate safety in the business.

Companies should use employee surveys to understand and improve Safety Leadership and Employee Engagement. Working to improve this shared ownership and responsibility will enhance your safety culture.

Continue risk reduction through a repeated process focused on operational risk and how to make worker jobs safer. Whether the problem is overexertion, slips, trips or falls, we can help you to understand risk and how to reduce it. Safety is a 24/7 proposition.

U se benchmarking and performance measurement to see how you safety efforts compare to your peer groups, how you have improved, and what gaps you have to close. Data strategies that allow for safety benchmarking, measuring improvement over baseline and predictive, prescriptive modeling Improving work safety is a topic, and a goal, that should be on everyone’s mind.

se benchmarking and performance measurement to see how you safety efforts compare to your peer groups, how you have improved, and what gaps you have to close. Data strategies that allow for safety benchmarking, measuring improvement over baseline and predictive, prescriptive modeling Improving work safety is a topic, and a goal, that should be on everyone’s mind.

According to the US Department of Labor, every year almost 6000 people are fatally injured at work. More than four million more people suffer non-fatal injuries, including over a million of which cause them to miss one or more days of work. What’s even worse than the bare statistics is that a great many of these deaths and injuries were due to carelessness and negligence, improper safety procedures and could have easily been avoided by paying more attention to safety guidelines.

Employers are required to provide a safe workplace, but ultimately your safety at work is your own responsibility. If you feel like your environment is unsafe and your complaints fall on deaf ears, you should look for employment elsewhere. Of course, some jobs and industries are inherently more hazardous than others and if you have one of these jobs, you’ll need to be extra vigilant. Deaths and injuries occur in all kinds of employment sectors and job descriptions, however – factories, construction, office work, farming, information technology, etc. The lack of work safety is a big problem and we should do everything we can to reduce the number of deaths and injuries at work.

complaints fall on deaf ears, you should look for employment elsewhere. Of course, some jobs and industries are inherently more hazardous than others and if you have one of these jobs, you’ll need to be extra vigilant. Deaths and injuries occur in all kinds of employment sectors and job descriptions, however – factories, construction, office work, farming, information technology, etc. The lack of work safety is a big problem and we should do everything we can to reduce the number of deaths and injuries at work.

Thankfully, there are a great many things you can do to improve your own personal safety at work. You can also create an atmosphere of safety awareness among your coworkers and supervisors, as well as lobby your employer to improve safety policies, practices, and training. Be pro-active when it comes to workplace safety. Don’t wait for others to pick up the ball. While you’re waiting, you may wind up getting injured. So take it upon yourself to do what you can to improve your own workplace safety.

Safety must be kept visible and present in the company workplace at all times. Safety banners are a very effective way to keep workers focused on safety while at work.